ما هي فوائد استخدام آلة تشكيل صوامع الحبوب؟

ما هي فوائد استخدام آلة تشكيل صوامع الحبوب؟

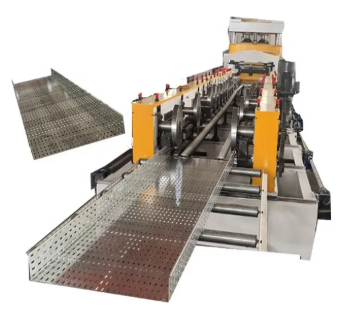

تخزين الحبوب يُعتبر أحد الجوانب الأكثر أهمية في الزراعة الحديثة وسلاسل الإمداد الغذائي. ومع زيادة الطلب العالمي على الغذاء واشتداد معايير التخزين، اكتسب بناء الصوامع الموثوقة والدائمة أهمية بالغة. وفي قلب هذه العملية الإنشائية تكمن آلة تشكيل صوامع الحبوب ، وهي معدة مصممة لتصنيع الألواح المموجة ومكونات أخرى تُستخدم في تجميع الصوامع.

الاختيار باستخدام آلة تشكيل صوامع الحبوب يوفر العديد من المزايا للمصنعين والمقاولين وحتى التعاونيات الزراعية. تتراوح هذه الفوائد من الدقة والكفاءة إلى الاستدامة وتوفير التكاليف، وهي فوائد متنوعة و extensive. ويستعرض هذا المقال هذه الفوائد بالتفصيل ويوضح سبب كون هذه المعدات محورية في مستقبل البنية التحتية لتخزين الحبوب.

فهم آلة تشكيل صوامع الحبوب

آلة تشكيل صوامع الحبوب هي معدات صناعية متخصصة تُستخدم لتحويل صفائح الصلب المسطحة إلى ألواح مموجة والعناصر الهيكلية المطلوبة لبناء صوامع الحبوب. وعادةً ما يتضمن العملية تغذية المادة الخام، وتسويتها، وثقب الثقوب، وتشكيل الشكل المموج باستخدام بكرات، وقطع الألواح إلى المقاس المناسب، وتكديسها للاستخدام في التجميع اللاحق.

الألواح التي تشكّلها الآلة تُعتبر اللبنات الأساسية للصوامع. ويمدّد تموّجها هذه الألواح بالقوة والمتانة، مما يسمح للصوامع بتحمل ضغط الحبوب الداخلي، والرياح، والعوامل البيئية الأخرى. وبالإضافة إلى الجدران، يمكن للآلة أيضًا تشكيل عناصر التقوية، وألواح السقف، والمكونات الأساسية، مما يجعلها حلاً متكاملاً ومتعدد الاستخدامات لبناء الصوامع بالكامل.

الفائدة الأولى: الدقة والسلامة الهيكلية

تعد الدقة واحدة من أهم الفوائد التي يحققها استخدام آلة تشكيل صوامع الحبوب. يجب أن تلبي الصوامع معايير دقيقة لضمان بقائها آمنة وعملية مع مرور الوقت. إذا لم تُشكَّل الألواح بشكل صحيح، فقد تواجه البنية مشكلات مثل التشويه أو التسرب، أو حتى الانهيار تحت الأحمال الثقيلة.

تحرص آلة التشكيل على إنتاج كل لوحة بشكل متسق من حيث الشكل والحجم وعمق التجويف. هذا التوحيد ينتج صوامع أقوى وأكثر موثوقية، والتي تتوافق مع لوائح السلامة ومعايير الصناعة. من خلال القضاء على التفاوتات، تحمي الآلة سلامة البنية وتحسّن عمر الصومعة الافتراضي.

الفائدة الثانية: الكفاءة والإنتاجية

غالبًا ما تواجه القطاع الزراعي ذروات موسمية في الطلب، حيث يجب توسيع سعة التخزين بسرعة. لا تستطيع الطرق الإنتاجية اليدوية أو القديمة مواكبة هذه المتطلبات. ترفع آلة تشكيل صوامع الحبوب من الكفاءة بشكل كبير من خلال أتمتة عملية التشكيل.

تسمح أنظمة التغذية عالية السرعة، والتشكيل المستمر للصفائح، والقطع الآلي بإنتاج كميات كبيرة من الألواح خلال فترة زمنية قصيرة. يعني هذا الزيادة في الإنتاجية أن المصانع قادرة على الوفاء بمواعيد تسليم المشاريع الضيقة، وتقليل فترات التسليم، وقبول المزيد من العقود دون التأثير على الجودة.

الفائدة الثالثة: توفير التكاليف

على الرغم من أن الاستثمار في آلة تشكيل صوامع الحبوب يتطلب رأس مالٍ كبيرًا في البداية، فإن التوفير على المدى الطويل يكون جيدًا بشكل ملحوظ. يقلل الإنتاج الآلي من تكاليف العمالة، ويحد من الأخطاء، ويقلل الحاجة لإعادة العمل. كما يتم تقليل هدر المواد بشكل كبير أيضًا لأن الآلات تقوم بتحسين استخدام الصفائح وتقلل من القطع الزائدة.

بالإضافة إلى ذلك، فإن الاتساق والمتانة في الألواح المُشكَّلة آليًا تقلل من تكاليف الصيانة بالنسبة لأصحاب الصوامع، مما يعزز أكثر من القيمة المقدمة للمصنّعين. مع مرور الوقت، يجعل العائد على الاستثمار آلة التشكيل خيارًا اقتصاديًا.

الفائدة الرابعة: المرونة والتخصيص

ليست جميع الصوامع مبنية بنفس الطريقة. قد يحتاج المزارعون والتعاونيات ومرافق التخزين الصناعية إلى أحجام أو سعات أو مواصفات تصميم مختلفة. توفر آلة تشكيل صوامع الحبوب المرونة اللازمة لإنتاج صفائح بطول متغير ومقاطع مموجة وأنماط ثقب مختلفة.

هذه المرونة تمكن المصنّعين من خدمة سوق أوسع، من الصوامع الصغيرة في المجتمعات إلى المجمعات الصناعية الكبيرة. كما تسمح القدرة على تخصيص المكونات للشركات بالاستجابة لمتطلبات المشاريع المحددة وتعزيز قدرتها التنافسية.

الفائدة الخامسة: الدمج مع الأتمتة والتكنولوجيا

غالبًا ما تكون آلات تشكيل صوامع الحبوب الحديثة متكاملة مع أنظمة أتمتة متقدمة. تتيح المزايا مثل التحكم العددي بواسطة الحاسوب (CNC) والوحدات المتحكمه المنطقية القابلة للبرمجة (PLC) والمراقبة في الوقت الفعلي للمشغلين برمجة الأبعاد ومتابعة الإنتاج والتأكد من ضمان الجودة.

تقلل الأتمتة الاعتماد على العمالة الماهرة مع الحفاظ على دقة عالية. يمكن للمستشعرات الذكية اكتشاف العيوب أثناء عملية الإنتاج وضبط العمليات تلقائيًا، مما يقلل من وقت التوقف. تجعل هذه التكاملات مع التكنولوجيا الحديثة ماكينات التشكيل جزءًا أساسيًا في التصنيع الذكي.

الفائدة السادسة: المتانة وتقليل الصيانة

يجب أن تتحمل صوامع الحبوب الاستخدام الكثيف لعقود من الزمن. وينطبق نفس المبدأ على الماكينات التي تصنع مكوناتها. صُمّمت ماكينة تشكيل صوامع الحبوب باستخدام مواد متينة تهدف إلى التشغيل المستمر. صُمّمت مكوناتها لتتحمل التآكل والتمزق، مما يوفر أداءً موثوقًا لفترات طويلة.

بالإضافة إلى ذلك، صُمّمت العديد من الماكينات بحيث تكون سهلة الصيانة. تقلل أنظمة البناء المودولارية والأجزاء القابلة للوصول والأنظمة التلقائية لزيت التشحيم من وقت التوقف ويُسهّل الإصلاحات. من خلال الاستثمار في معدات متينة، يضمن المصنعون استمرارية الإنتاج ويقللون من التكاليف المرتبطة بالصيانة المتكررة.

الميزة السابعة: الاستدامة والمسؤولية البيئية

تُعد الاستدامة محور اهتمام متزايد في الزراعة والتصنيع. تدعم آلة تشكيل صوامع الحبوب هذه هذه الأهداف من خلال تحسين استخدام المواد وتقليل الهدر وإنتاج ألواح فولاذية قابلة لإعادة التدوير. كما تُسهم المحركات الموفرة للطاقة وأنظمة إدارة الطاقة الذكية في تقليل الأثر البيئي للإنتاج.

وبالإضافة إلى ذلك، فإن العمر الطويل للصوامع المُنشأة باستخدام الألواح المُشكَّلة آليًا يقلل الحاجة إلى إعادة البناء بشكل متكرر، مما يُسهم في خفض البصمة الكربونية الإجمالية للبنية التحتية للتخزين. من خلال اعتماد هذه التقنية، تُظهر الشركات التزامها بالممارسات المسؤولة بيئيًا.

الميزة الثامنة: الميزة التنافسية في السوق

في سوق عالمي حيث تحدد الجودة والسرعة والكفاءة من حيث التكلفة القدرة التنافسية، يمنح ماكينة تشكيل صوامع الحبوب الشركات ميزة واضحة. من خلال تقديم منتجات عالية الجودة بسرعة وثبات، يمكن للمصنّعين بناء سمعة قوية، وجذب عملاء متكررين، وتوسيع حصتهم في السوق.

تقديم خيارات تخصيص واعتماد ممارسات صديقة للبيئة وأداء موثوق به يُعدّ من العوامل التي تميز الشركات عن منافسيها. وللشركات التي تسعى إلى النمو على المستوى الإقليمي أو الدولي، فإن الاستثمار في ماكينة تشكيل يُعدّ ميزة استراتيجية.

تطبيقات ماكينة تشكيل صوامع الحبوب

تتعدّد تطبيقات هذه الآلة لتغطي مختلف السياقات الزراعية والصناعية. تستخدم المزارع التجارية الكبيرة الصوامع التي تنتجها هذه الآلات لتخزين الحبوب مثل القمح والذرة والأرز. وتعتمد الجمعيات الزراعية التعاونية عليها لتخزين الحبوب جماعيًا من أجل استقرار الأسعار وتقليل خسائر ما بعد الحصاد. وتحتاج مصانع معالجة الأغذية الصناعية إلى الصوامع لتخزين المواد الخام، في حين تستخدمها الموانئ ومحطات اللوجستيات لتنظيم صادرات وواردات الحبوب السائبة.

وبالإضافة إلى القطاع الزراعي، تُستخدم الألواح التي تشكّلها الآلة أيضًا في الصناعات ذات الصلة حيث يُحتاج إلى صفائح الصلب المموجة لأغراض التخزين أو التدعيم الهيكلي أو حتى لبناء مباني صناعية. إن مرونة هذه الآلة تضمن بقائها ذات قيمة في قطاعات متعددة.

مستقبل آلات تشكيل صوامع الحبوب

مع تزايد أمن الغذاء العالمي، سيستمر الطلب على حلول تخزين فعالة وموثوقة في الارتفاع. من المتوقع أن تتطور آلة تشكيل صلب الحبوب مع ميزات جديدة مثل الذكاء الاصطناعي للصيانة التنبؤية، وتوصيل إنترنت الأشياء للمراقبة عن بعد، وعمليات تشكيل أكثر استدامة.

قد توفر الآلات المستقبلية تخصيصًا أكبر، مما يتيح للمصنعين تلبية متطلبات فريدة مع الحد الأدنى من التدخل اليدوي. مع تحرك الزراعة نحو التحول الرقمي، ستندمج آلات التشكيل بسلاسة في المصانع الذكية وسلاسل التوريد المتصلة.

الاستنتاج

مزايا استخدام آلة تشكيل الصوامع واضحة وبعيدة المدى. تجعل الدقة والكفاءة والادخار في التكاليف والمرونة والمتانة والاستدامة والقدرة التنافسية في السوق من هذا المعدّات ضرورية لإنتاج الصوامع الحديثة. من خلال الاستثمار في تقنيات تشكيل متقدمة، لا يحسّن المصنعون عملياتهم فحسب، بل يسهمون أيضًا في تحقيق الأمن الغذائي العالمي والتنمية المستدامة.

الأسئلة الشائعة

ما هي آلة تشكيل صوامع الحبوب؟

هي آلة تقوم بتحويل صفائح الفولاذ المسطحة إلى ألواح مموجة ومكونات أخرى تُستخدم في بناء صوامع الحبوب.

لماذا تُعد الدقة مهمة في إنتاج الصوامع؟

تُساهم الألواح الدقيقة في ضمان سلامة البنية، ومنع التشويه وتحسين السلامة والمتانة العامة للصوامع.

كيف تُحسّن آلة تشكيل صوامع الحبوب الكفاءة؟

تقوم الآلة بأتمتة عمليات التغذية والتشكيل والقطع، مما يسمح بإنتاج كميات كبيرة من الألواح بسرعة وثبات.

هل تعد آلة التشكيل استثمارًا اقتصاديًا؟

نعم، رغم الاستثمار الأولي، إلا أنه يقلل من تكاليف العمالة، ويحد من الأخطاء، ويقلل من المصروفات التشغيلية على المدى الطويل.

هل يمكن للآلة التعامل مع تصميمات مختلفة للأبراج؟

نعم، يمكنها إنتاج ألواح بأطوال مختلفة، وتصميمات مموجة متنوعة، وأنماط ثقب مختلفة، مما يسمح بالتعديل لتلبية متطلبات المشاريع المختلفة.

ما الدور الذي تلعبه الأتمتة في آلات التشكيل؟

تُحسّن الأتمتة الدقة، وتقلل الاعتماد على العمالة الماهرة، وتدمج مراقبة الجودة في الوقت الفعلي.

هل هذه الآلات متينة؟

تم تصميمها بقطع قوية تتحمل التشغيل المستمر، وغالبًا ما تكون مزودة بخصائص صيانة سهلة لتمديد عمرها الافتراضي.

كيف تدعم آلة التشكيل الاستدامة؟

تقلل من هدر المواد، وتستخدم الطاقة بكفاءة، وتنتج ألواحًا من الصلب قابلة لإعادة التدوير، مما يقلل من الأثر البيئي.

من يستفيد من استخدام هذه التكنولوجيا؟

يستفيد مصنعو الصوامع والتعاونيات الزراعية ومعالجو الأغذية الصناعية ومحطات اللوجستيات من تشكيل الآلات.

ما هي الاتجاهات المستقبلية التي ستُشكّل تطوّر هذه الآلات؟

سيُحدد الجيل التالي من آلات التشكيل الذكاء الاصطناعي والتكامل مع إنترنت الأشياء والتخصيص المتقدم والعمليات الإنتاجية المستدامة.

EN

EN